Our Process

Expert Residential and Commercial Concrete Coatings Installation Process

Preparation

We diamond grind the concrete floors with up to 800 Lb machines to open up the pores of the concrete. This allows for maximum base coat adherence to your substrate. Then use industrial HEPA vacuums that collect up to 90% of the dust.

Concrete Reconstruction

Our Polyurea menders are used to fix pitting and cracks before the concrete coating is applied to ensure as perfect of a finished product as possible.

Basecoat

98% solids Polyurea concrete coatings basecoat is mixed and applied to the prepped surface. It soaks deep down into the surface, forming a permanent bond with the substrate. This allows for expansion and contraction during season changes, guaranteeing our product warranty!

Broadcasting

the Flake

The flake is broadcast by hand to rejection, meaning the floor can’t take anymore. This ensures an even coat of color and texture guaranteed to impress.

Scraping the

Flake

Once the base coat is fully cured, the concrete floor is scraped and vacuumed to remove loose or vertical flakes. We then vacuum up any loose flakes before the final coat.

Topcoat

Application

The final step is to squeegee and back-roll the non-porous Polyaspartic clear coat.

We Are Dedicated to Providing Quality and Service

Your Seamless Experience from Start to Finish

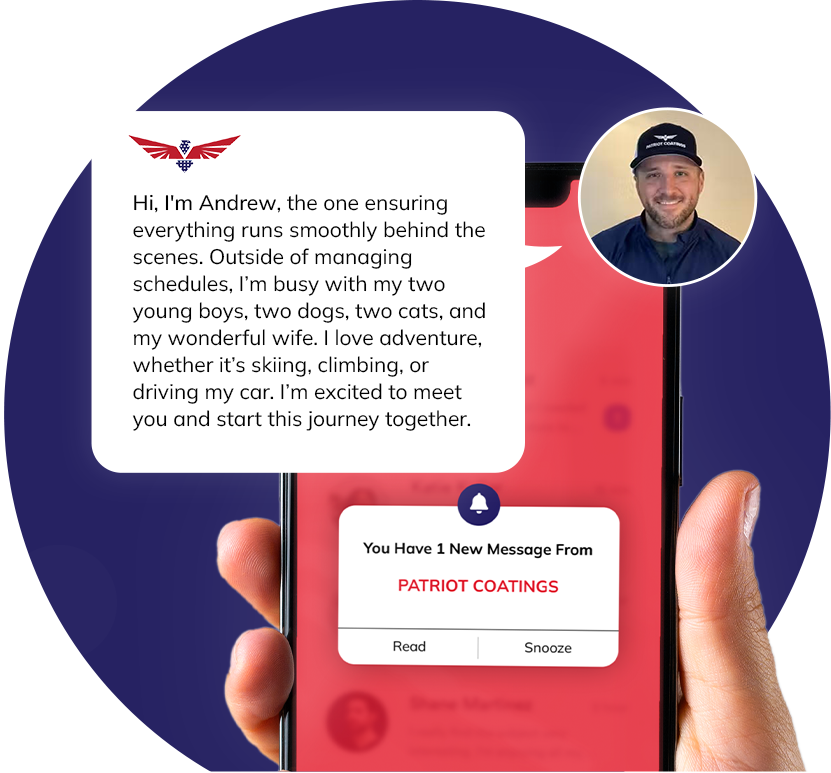

At Patriot Coatings, we pride ourselves on delivering an exceptional customer experience from start to finish.

Here’s what you can expect when you choose us:

Schedule a Quote

Contact us to set up a convenient time for a detailed quote. You’ll receive a picture of the team member who will visit, so you know exactly who to expect.

Automated Reminders

Expert Assessment

Seamless Installation & Follow-Up

We handle the installation with care and precision. We’ll follow up to ensure your satisfaction and address any questions or concerns.

Notification

Get to Know Your Expert Before the Visit

testimonials

What Our Customers Say